HTCC, or High-Temperature Co-Fired Ceramics, involves preparation temperatures of 1300 to 1600°C, differing from LTCC (Low-Temperature Co-Fired Ceramics). In HTCC, thick film screen printing creates circuitry. This process prints high-melting-point metals like tungsten, molybdenum, and manganese onto green ceramic substrates. After layering, they undergo high-temperature sintering.

HTCC is applied in various fields due to its excellent properties, especially in demanding environments. Key applications include:

Microwave Device Packaging: Used for RF and microwave circuits in communications and radar systems.

Large Integrated Circuit Packaging: Ideal for packaging large ICs with superior thermal conductivity and mechanical strength.

Hybrid Integrated Circuit Packaging: Integrates resistors, capacitors, and inductors into a single design for high-density integration.

Optoelectronic Device Packaging: Packaging for LEDs and lasers that meets high-temperature and high-power demands.

High-Temperature Sensors: Suitable for extreme environmental monitoring due to high-temperature resistance.

Power Components: Provides electrical insulation and thermal management in power modules for high-power solutions.

These applications highlight HTCC’s importance in technology-driven markets, particularly in aerospace, military, and medical sectors.

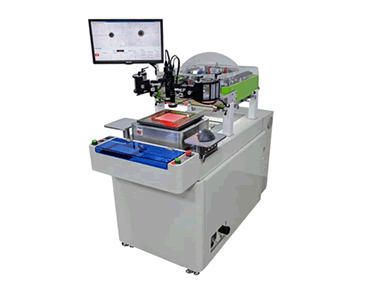

To prepare HTCC, high-precision thick film printing are essential for processes like ceramic shell packaging, substrates, and heating bodies. In response to market needs, WISDOM has developed HTCC-specific Thick Film Screen Printer. These printers come with customized platforms for various shapes and areas. The via filling technology is mature, with successful cases in mass production.

Sensor Thick Film Screen Printer